Categories

Categories

- Home

- Mining and Oil

- Mining

- Lake Superior, Iron and Chemical Company circa 1906 (Michigan mining)

Lake Superior, Iron and Chemical Company circa 1906 (Michigan mining)

Lake Superior, Iron and Chemical Company circa 1906 (Michigan mining)

Product Description

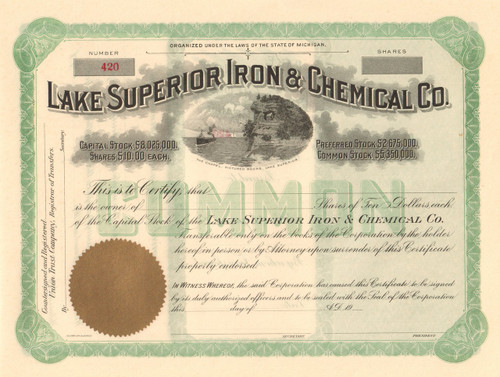

Lake Superior, Iron and Chemical Company stock certificate circa 1906

Fantastic mining piece with a Lake Superior iron ore ship passing near the rocky outcrop ("The Chapel") Unissued and not cancelled. Unusual color background. Circa 1906 from company records.

Abijah Weston formed the Manistique Iron Company in 1887 and the Weston Furnace Company in 1890. These industries were located at the North end of Furnace Street, now North Cedar Street. Charcoal was made in bee-hive type buildings and then used in the furnaces to melt iron ore pellets and make pig iron, which was shipped throughout the United States.

In 1906, the Burrell Chemical Company bought the companies, creating the Lake Superior Iron and Chemical Company. By 1913, the Lake Superior Iron and Chemical Company was foreclosed upon due to a soft iron market. In 1915, a new company was formed by American, Canadian, and British interests called the Charcoal Iron Company of America. The Company remained in business until 1925 when the business declared bankruptcy.

The Lake Superior Iron and Chemical Company was the predessor company to the Charcoal Iron Company of America and manufactured pig iron, acetone and acetate, and alcohol. The company was originally formed in 1907 by Mr. Joseph Berry as a consolidation of some of his numerous holdings, including the Ashland Iron & Steel Company, Manistique Iron Company, Burrell Chemical Company, Michigan Iron Company, Superior Chemical Company, Northern Charcoal Iron Company, Elk Rapids Iron Company and the Boyne City Iron Company.

Lake Superior Iron and Chemical Company; general offices, Detroit. Officers: Elisha H. Flinn, President; William 0. Sharp, First Vice President; E. G. Rust, Second Vice President; John Christian, Secretary; William D. Smith, Treasurer; and C. F. Fraser, Assistant Treasurer. Selling Agenda: Superior Charcoal Iron Company, Grand Rapids, Mich., for pig iron made by the Manistique, Chocolay, Elk Rapids, Newberry, and Boyne City plnnts; and Rogers, Brown & Co., Cincinnati and branch houses, for pig iron made by the Ashland Plant.

Capital stock authorized, $7,500,000, all common. Bonds authorized, 16,000,000. The Lake Superior Iron and Chemical Company operated the blast furnaces and other plants described below:

Ashland Plant, Ashland, Wis. One stack, 60 x 12, built in 1887- 8 and blown in in March, 1888; remodeled in 1897; closed top; two Whitwell stoves; hot blast; fuel, charcoal; ore, Lake Superior ; product, foundry, car-wheel, and malleable pig iron; annual capacity, 45,000 tons. Brand, "Hinkle." Charcoal kilns are connected with the furnace; also a plant for the manufacture of wood alcohol and acetate of lime; also a machine shop. Selling agents, Rogers, Brown & Co., Cincinnati and branch houses. (Formerly called the Hinkle Furnace and operated by the Ashland Iron and Steel Company; acquired by the Lake Superior Iron and Chemical Company on May 1, 1907.)—Act in- in 1907.

Boyne City Plant, Boyne City, Mich. One stack, 60 x 101, built in 1903—1, utilizing machinery from the abandoned Martel Furnace at St. Ignace, Mich., and blown in January 1, 1905; two Kloman fire-brick stoves, each 60 x 154; fuel, charcoal; ore, Lake Superior from the Marquette and Menominee districts; product, car-wheel and malleable pig iron; annual capacity, 29,000 tons. Selling agent, the Superior Charcoal Iron Company, Grand Rapids. (Formerly called Pine Lake Furnace and operated by the Boyne City Charcoal Iron Company; acquired by the Lake Superior Iron and Chemical Company on May 1, 1907.)—Active in 1907, Chocolay Plant, Chocolay, Mich. One stack, 68 x 10, built in 1860 and rebuilt in 1800; long inactive; rebuilt and revived in 1907 by the Northern Charcoal Iron Company; two iron pipe stoves (one 24 and one 32-inch); fuel, charcoal; ore, Lake Superior; product, foundry, car-wheel, and malleable pig iron; annual capacity, 2.1,000 tons. Charcoal kilns are connected with the furnace. Selling agent, the Superior Charcoal Iron Company, Grand Rapids. (Formerly called the Chocolay Furnace and owned but never operated by the Northern Charcoal Iron Company; acquired by the Lake Superior Iron and Chemical Company on May 1, 1907.)—Being rebuilt; to be ready for blast in September or October, 1907.

Elk Rapids Plant, Elk Rapids, Mich. One stack, 64 x 11, first put in blast in July, 1873; rebuilt in 1902; hot blast; fuel, charcoal; ore, Lake Superior exclusively; specialties, Nos. 3 and 4 pig iron for ear wheels and malleable castings; annual capacity, 35,000 tons. Brand, "Elk Rapids." Charcoal kilns arc connected with the furnace; also a plant for the manufacture of wood alcohol and acetate of lime; also a machine shop. Selling agent, the Superior Charcoal Iron Company, Grand Rapids. (Formerly called the Elk Rapids Furnace and operated by the Elk Rapids Iron Company; acquired by tho Lake Superior Iron and Chemical Company on May 1, 1907.)—Active in 1907.

Newberry Plant, Newberry, Mich. One stack, 51 1/2 x 10 1/2, built in 1882-3 and blown in May, 1883; rebuilt in 1892 and 1903: closed top; four iron stoves; warm blast; water jackets; fuel, charcoal; ore, Lake Superior; product, car-wheel and malleable pig iron; annual capacity, 29,000 tons. Brand, "Michigan." Charcoal kilns are connected with the furnace; also a plant for the manufacture of wood alcohol and acetate of lime. Selling agent, the Superior Charcoal Iron Company, Grand Rapids. (Formerly operated by the Michigan Iron Company, Limited; acquired by the Lake Superior Iron and Chemical Company on May 1, 1907.)

In addition to the blast furnaces enumerated the Lake Superior Iron and Chemical Company acquired from the Manistique Iron Company, at Manistique, 84 charcoal kilns with a capacity of 65 cords each; also 30 charcoal kilns with a capacity of 65 cords each from the Northern Charcoal Iron Company, at Chocolay; 61 charcoal kilns and a plant for the manufacture of wood alcohol and acetate of lime from the Elk Rapids Iron Company, at Elk Rapids; 84 charcoal kilns and a plant for the manufacture of wood alcohol and acetate of lime from the Ashland Iron and Steel Company, at Ashland; and 58 charcoal kilns with a capacity of 90 cords each from the Michigan Iron Company, Limited, at Newberry.

In addition the Lake Superior Iron and Chemical Company acquired from the Bun-ell Chemical Company, of Manistique, Mich., and the Superior Chemical Company, of Newberry, Mich., works for the manufacture of wood alcohol and acetate of lime. Plants for the manufacture of these products will probably be installed shortly at the blast furnaces of the company which arc not now equipped with plants for the recovery of charcoal by-products.

The Lake Superior Iron and Chemical Company through the purchase of the properties above described also acquired considerably over two hundred thousand acre? of timber lands in Michigan and Wisconsin, together with a number of railroads and extensive iron-ore mines in the Lake Superior region.

Loading... Please wait...

Loading... Please wait...